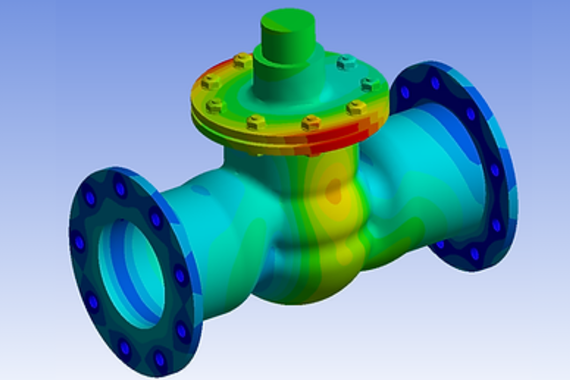

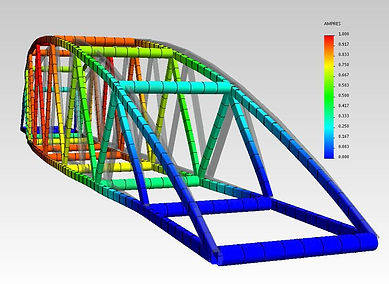

At Forcyst, we use Finite Element Analysis (FEA) to validate the performance and identify potential failure modes of a designed product. Once a concept is designed and approved, we prepare a problem statement, set the boundary conditions, and conduct FEA to ensure the product meets design criteria without over-engineering.

We perform two types of FEA:

1. Static Analysis

Examines the product with no internal effects, vibrations, or impacts.

2. Linear Analysis

Considers linear geometry, material properties, and no contact.

FEA is carried out using software, including CFD, to test and analyze the product with actual material properties. Although FEA adds some cost to the project, it saves time by preventing over- or under-designed prototypes. This method also supports Failure Mode and Effects Analysis (FMEA) studies.

The benefits of FEA include reducing project time and cost by accurately testing the product during the design process.

If you’d like to discuss your project, please contact us at [email protected].

Types of Finite Element Analysis:

Stress Analysis

Thermal Analysis

Vibration Analysis

Impact Analysis

Crash Analysis