Computer-Aided Engineering (CAE) and modern manufacturing techniques have transformed traditional design methods. By focusing on simulation and analysis, we can achieve important design and manufacturing goals.

Several CAE techniques are commonly used for optimizing structures:

Topology Optimization

Shape Optimization

Parametric Optimization

Design Space Exploration

Lightweight Design

Reducing the weight of components.

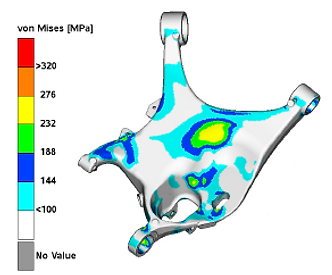

Stress Reduction

Lowering stress in specific areas.

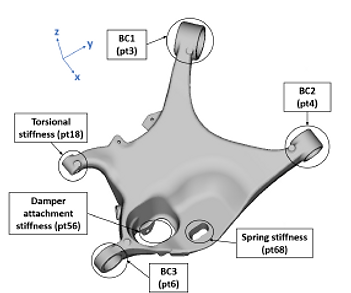

Boundary Compliance

Ensuring designs meet various boundary conditions.

Component Reliability

Decreasing the likelihood of component failure.

Material Efficiency

Using less material without compromising strength.

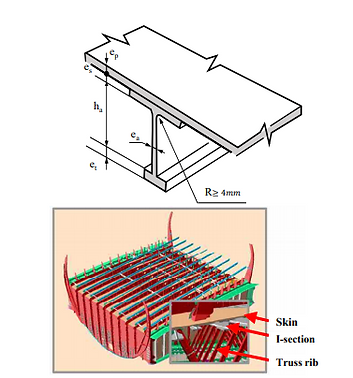

- Size Optimization

We provide educational Excel spreadsheets to help kickstart your project. These include calculations for shells, heads, nozzles, and flat cone layouts.

This aims to reduce stress in certain areas while meeting all boundary conditions and loads. It uses methods like the optimality criteria to ensure uniform stress distribution and minimize stress concentration by altering the structure’s shape.

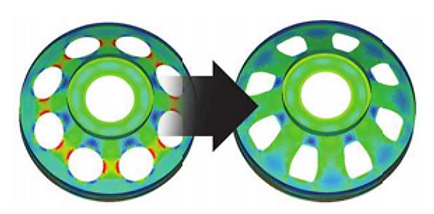

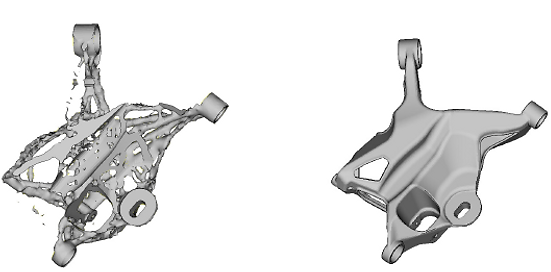

3. Topology Optimization:

- Topology optimization determines the best material layout within a given design space while satisfying all boundary conditions and load requirements. Techniques include:

- Solid Isotropic Material with Penalization (SIMP)

- Evolutionary Structural Optimization (ESO)

- Bi-directional Evolutionary Structural Optimization (BESO)

- SIMP is the most commonly used method, focusing on maximizing stiffness for a given amount of material, which improves computational efficiency.

By using these advanced techniques, designers can create more effective and efficient structures that meet modern engineering challenges.

Fig: Prior to Design Realization Fig: Final Design Realization